Model No.: XY-7-P

Brand: JinPeng

Warranty: 1 Year

Automatic Grade: Automatic

Power Source: Other

Type: Tire Recycling Machine

Name: Waste Tire Plastic Pyrolysis Plant

Capacity: 5-12Mt

Fuel Choice: Coal, Wood, Gas, Oil

Door Model: Full Open Door

Heating Method: Direct

Operating Mode: Intermittent Operation

Structure: Horizontal Rotation Type

Oil Yield: 40%~50%

Cooling: Cycling Water

Type Of Drive: External Annular Gear

Packaging: 2*40HQs for 5 tons 1*40HQ+1*40FR for 10 tons All goods are packed with export standard package to make sure no damage during transportation.

Productivity: 60sets/Month

Transportation: Ocean

Place of Origin: China(Mainland),Henan

Supply Ability: 60sets/Month

Port: Lianyungang

Payment Type: L/C,T/T

Incoterm: FOB

Intermittent Operation Rubber Tire Recycling Machine

We are the first domestic professional institute in the recycling and utilization of waste resources (waste plastics, waste rubber, tyres and waste engine oil).

Now, our company holds several items which are China national patents (No.: 200720091524.1,etc.), CE (No.:001460.1C2), ISO 9001:2008 (NO.:08910Q21324R0M) and ISO 14001:2004 (NO.08910E2026R0M) related with the involved our technology and equipments.

On Waste plastics, city garbage, scrap tires, we developed series of machine for disposing scrap tyre and plastic that includes 5~10MT daily capacity on batch systems, 10~15MT systems of semi-continuous systems, 10~30mT daily capacity fully continuous, automatic systems accordingly.

For the crude oil, used engine oil, pyrolysis fuel oil, we developed 3~6Mt batch systems and 20~300Mt continuous systems for the distillation and refining.

Besides, we developed related tires/plastics shredding machines, carbon black deep-process machines to help customers complete solution on the waste in a clean, dust/pollution free ways.

Advantages of Batch Waste Tyre Pyrolysis Plant:

1.Full open door design: Speedy loading in and steel pulling out; Easily cooling down after one batch finished, saving time; No leaking with special high temperature flexible graphite packing.

2.Unique Craft Condensers: High condensing efficiency with more oil output. Good quality oil, longer lifetime, and easy to clean.

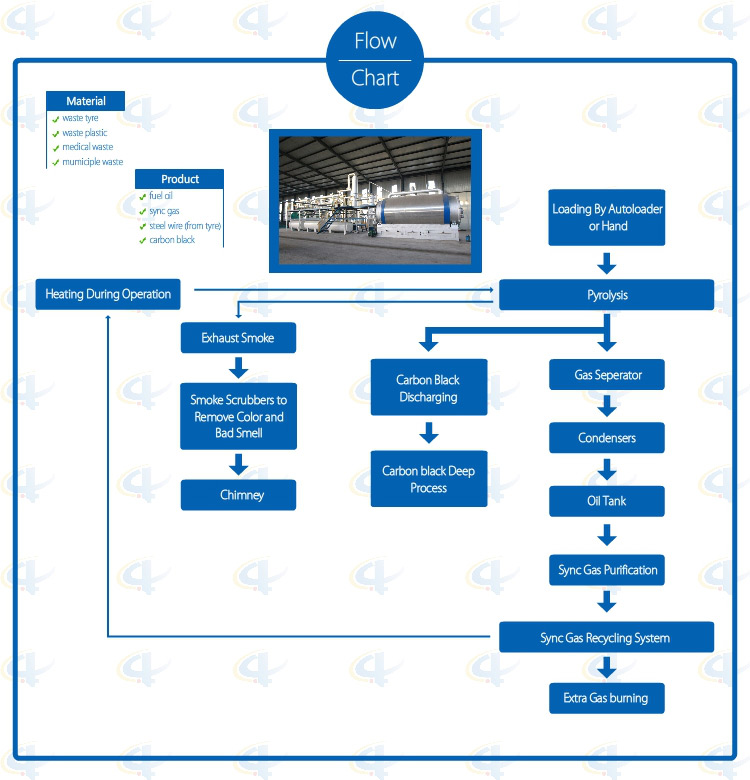

3.National Patent Unique Smoke Scrubbers: More efficient removal of the acid gas and dust of the smoke by neutralization, purification and absorption, environmental friendly without pollution.

4.National Patent Carbon Black Discharging System: Speedy fully enclosed Auto-discharging under high temperature, avoiding carbon black pollution, saving time.

5.Automatic Submerged welding technology, ultrasonic nondestructive testing, both manual and the automatic safety devices.

6.Sync Gas Recycling System: Fully burned after recycling and utilization, saving fuel and preventing pollution.

7.Direct Heating System: Enlarging heating square to lengthen the lifespan of the reactor and easy to control the temperature.

8.National Patent, unique heat insulation shell; high efficiency temperature keeping, excellent energy-saving effect.

Batch Waste Tyre Pyrolysis Plant:

Pyrolysis Plant is used for recycling waste tire, waste plastic, waste rubber to fuel oil. According to the actual situation in every country and district, we developed different models of Batch Pyrolysis Plants for waste tires, rubber and plastic with daily capacity 5 -10 tons.

Flowchat of Batch Waste Tyre Pyrolysis Plant

Technical Parameter of Batch Waste Tyre Pyrolysis Plant

NO. Item Technical Parameter 1 Equipment Model XY-7 2 Door Model Full Open Door 3 Suitable Raw Materials Rubber/Plastic Products 4 Structure Horizontal Type Revolves 5 Reactor Size Φ2200*6000mm Φ2600*6600mm 6 Capacity for One Batch 5-6Mt; 8-10Mt 7 Oil Yield of Tires 40%-45% 8 Work Pressure Normal Pressure 9 Reactor Rotation Speed 0.4R/M 10 Fuels Choice Coal, Wood 11 Power 18KW/H 12 Cooling Method Water Cycling 13 Type of Drive External Annular Gear 14 Heating Method Direct 15 Type of Installation With Foundation 16 Noise dB(A) ≦85 17 Operation Mode Intermittent Operation 18 Total Weight(MT) 25-40 19 Installation Space Required 30m*10m 20 Manpower 3~4/batch 21 Shipment Ф2200×6000=1*40HC+1*40FR

Ф2600×6600=2*40HC+1*40FR

Plants Delivery

Installation Cases

Our Customers

Company Introduction

Product Categories : Waste Tyre Pyrolysis Plant > Batch Waste Tyre Pyrolysis Plant